AWS A5.13 ENiCrFe-1 Nikel alloys Manual elektroda Welding aksesoris

Aplikasi & Standar

COBALT-BASED SURFACING ELECTRODE iki bisa digunakake kanggo lining SLEEVE OF SHAFT SLEEVE, CUTTING EDGE OF CHEMICAL FIBER EQUIPMENT, SAWTOOTH, SCREW PUSH ROD, HIGH temperature and HIGH pressure VALVE AND HIGH pressure pump DLL. The roughness lumahing workpiece kudu kurang saka Ra12.5μm, lan lumahing teyeng, lenga lan rereget kudu strictly dibusak. Matriks ngirim ora retak, pori, wedhi lan cacat liyane, lan sudhut lan sudhut kudu dibunderaké. Sadurunge lumahing, suhu sing beda kudu dipilih miturut materi substrat kanggo preheating. Nalika materi matriks baja tahan panas pearlitic utawa stainless steel martensitic lan bahan liyane karo kinerja welding miskin, lapisan lumahing stainless steel austenitic kudu gandheng ing lumahing matriks, lan banjur alloy basis kobalt kudu surfacing sawise Processing Gamelan kanggo nambah resistance retak lan supaya retak. Salah siji sumber daya welding busur AC utawa DC bisa digunakake kanggo elektroda D802 lan D812. Dc arc welding power supply dianjurake.

Fitur

GEH-SL12 titanium calcium coated kobalt-base surfacing electrode. Kobalt-cr-tungsten alloy digunakake minangka kabel inti. Dc sambungan mbalikke dianjurake. logam lumahing bisa njaga resistance nyandhang apik lan resistance karat ing 650 ℃. Sadurunge welding, iku kudu panggangan ing 300-350 ℃ kanggo 1 jam; Lapisan hardening ing lumahing logam dhasar kudu dibusak supaya retak lan brittleness. Miturut ukuran workpiece logam dhasar lan jinis logam dhasar, iku kudu preheated ing 300-600 ℃, lan welding busur cendhak saiki cilik cocok.

Perusahaan & Pabrik

Komposisi produk lan sifat mekanik introduksi

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | P | Fe | Nb+Ta | S |

| ATURAN GB/T | 0.08 | 3.5 | 0.80 | 13.0-17.0 | ≥62 | 0.02 | 11.0 | 0.5-4.0 | 0.015 |

| ATURAN AWS | 0.08 | 3.5 | 0.75 | 13.0-17.0 | ≥ | 0.03 | 11.0 | 1.5-4.0 | 0.015 |

| NILAI CONTOH | 0.048 | 2.97 | 0.34 | 15.6 | 69.6 | 0.005 | 8.94 | 2.65 | 0.007 |

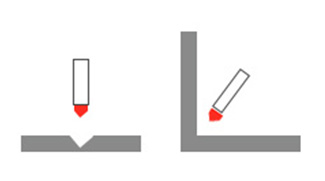

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 2.6*300 | 3.2*350 | 4.0*350 | |||||

| LISTRIK (Amp) | Pengelasan datar/horizontal | 69-95 | 70-115 | 95-145 | ||||

| Pengelasan vertikal/overhead | 55-80 | 65-110 | 80-130 | |||||

KASUS KHAS

Sertifikat

Komposisi produk lan sifat mekanik introduksi

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | P | Fe | Nb+Ta | S |

| ATURAN GB/T | 0.08 | 3.5 | 0.80 | 13.0-17.0 | ≥62 | 0.02 | 11.0 | 0.5-4.0 | 0.015 |

| ATURAN AWS | 0.08 | 3.5 | 0.75 | 13.0-17.0 | ≥ | 0.03 | 11.0 | 1.5-4.0 | 0.015 |

| NILAI CONTOH | 0.048 | 2.97 | 0.34 | 15.6 | 69.6 | 0.005 | 8.94 | 2.65 | 0.007 |

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 2.6*300 | 3.2*350 | 4.0*350 | |||||

| LISTRIK (Amp) | Pengelasan datar/horizontal | 69-95 | 70-115 | 95-145 | ||||

| Pengelasan vertikal/overhead | 55-80 | 65-110 | 80-130 | |||||