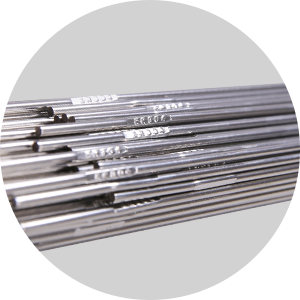

Baja tahan karat Elektroda manual E410NiMo-16 Sambungan solder

Aplikasi

Cocog kanggo nyandhang tutup luwih nuntut lan resistance karat, rotor turbin hydraulic lan welding liyane

Badan Sertifikasi: JIS

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| ATURAN GB/T | 0.06 | 1.00 | 0.90 | 11.0-12.5 | 4.0-5.0 | 0.40-0.70 | 0.04 | 0.03 | 0.75 | |

| ATURAN AWS | 0.06 | 1.00 | 0.90 | 11.0-12.5 | 4.0-5.0 | 0.40-0.70 | 0.04 | 0.03 | 0.75 | |

| NILAI CONTOH | 0,028 | 0.45 | 0.6 | 11.6 | 4.8 | 0.55 | 0,026 | 0.007 | 0.13 | |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | HEATTREAMENT ℃ xh | NILAI IMPAK J/℃ | ELONGASI(%) | ||||||

| ATURAN GB/T | - | 760 | 595-620x1 | - | 10 | ||||||

| ATURAN AWS | - | 760 | 595-620x1 | - | 15 | ||||||

| NILAI CONTOH | - | 925 | 620x1 | - | 17 | ||||||

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| LISTRIK (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | ||||||

Titanium-kalsium martensit elektroda stainless steel, komposisi utama 11,5% Cr-4,5% Ni-0,55% Mo;

Amarga tambahan komponen alloy NiMo, resistance karat luwih stabil, atose lan resistance nyandhang suhu dhuwur sing apik, lan retak kadhemen wis èfèktif nyegah. Kekerasan las kira-kira 270HB.

Busur stabil, mbentuk ayu, ripple alus, cipratan sethitik, aman slag gampang, resistance geni apik, resistance porositas apik.

Ningbo Honest Metal Materials Co, Ltd.is perusahaan profesional welding internasional ing riset lan pangembangan, produksi, penjualan lan manajemen. Iki diadegaké ing 2020.

9.000 ton bahan kimia

Zhejiang Petrochemical 40 yuta ton/taun proyek integrasi refinery

Zhangjiagang Hanzhong Cryogenic Technology Co., LTD. Wadhah panyimpenan lan transportasi suhu rendah

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| ATURAN GB/T | 0.06 | 1.00 | 0.90 | 11.0-12.5 | 4.0-5.0 | 0.40-0.70 | 0.04 | 0.03 | 0.75 | |

| ATURAN AWS | 0.06 | 1.00 | 0.90 | 11.0-12.5 | 4.0-5.0 | 0.40-0.70 | 0.04 | 0.03 | 0.75 | |

| NILAI CONTOH | 0,028 | 0.45 | 0.6 | 11.6 | 4.8 | 0.55 | 0,026 | 0.007 | 0.13 | |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | HEATTREAMENT ℃ xh | NILAI IMPAK J/℃ | ELONGASI(%) | ||||||

| ATURAN GB/T | - | 760 | 595-620×1 | - | 10 | ||||||

| ATURAN AWS | - | 760 | 595-620×1 | - | 15 | ||||||

| NILAI CONTOH | - | 925 | 620×1 | - | 17 | ||||||

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| LISTRIK (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | ||||||

Tulis pesen sampeyan ing kene lan kirimake menyang kita