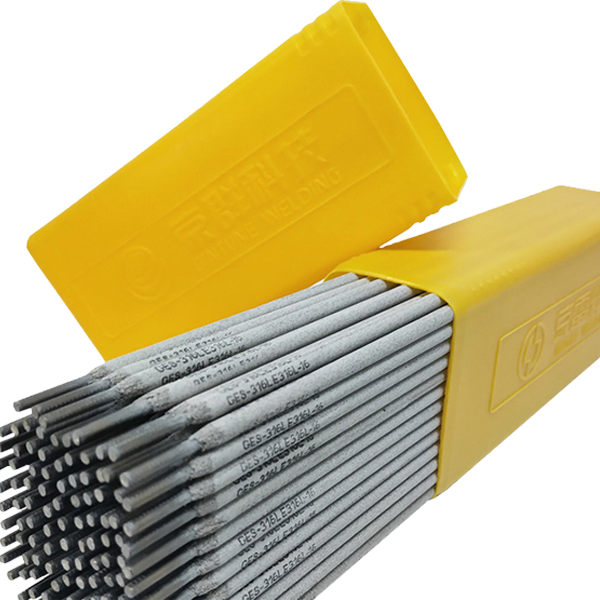

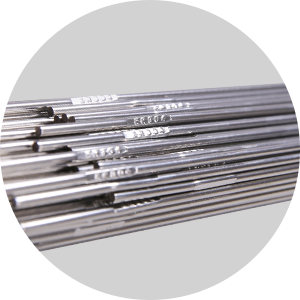

Baja tahan karat Elektroda manual E2209-16 Data solder

Aplikasi

Ditrapake kanggo welding baja cocog 00Cr22Ni5Mo3N (SUS2205) lan S31803 duplex stainless steel ngemot 22% Cr ing industri petrokimia.

Badan sertifikasi: ABS, BV, CCS, DNV/GL, LR, NK, CE

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | N | |

| ATURAN GB/T | 0.04 | 0.5-2.0 | 1.00 | 21.5-23.5 | 7.5-10.5 | 2.5-3.5 | 0.04 | 0.03 | 0.08-0.20 | |

| ATURAN AWS | 0.04 | 0.5-2.0 | 1.00 | 21.5-23.5 | 8.5-10.5 | 2.5-3.5 | 0.04 | 0.03 | 0.08-0.2 | |

| NILAI CONTOH | 0,026 | 0.75 | 0.65 | 22.8 | 9.4 | 3.3 | 0,028 | 0.005 | 0.14 | |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | NILAI IMPAK J/℃ | ELONGASI(%) | ||||

| ATURAN GB/T | - | 690 | - | 15 | ||||

| ATURAN AWS | - | 690 | - | 20 | ||||

| NILAI CONTOH | - | 835 | 40/-40 | 26 | ||||

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| LISTRIK (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||

Elektroda tangan stainless steel kalsium titanium kanthi komposisi utama 22% Cr-9% Ni-3% Mo-N;

logam molten ngandhut bab 40% ferit, loro austenitic lan ferritic stainless steel kinerja lengkap, pitting lan kaku resistance karat banget;

Busur stabil, mbentuk ayu, ripple alus, cipratan sethitik, aman slag gampang, resistance geni apik, resistance porositas apik.

Ningbo Honest Metal Materials Co, Ltd.is perusahaan profesional welding internasional ing riset lan pangembangan, produksi, penjualan lan manajemen. Iki diadegaké ing 2020.

210.000 ton operator akeh jinis Newcastle

Zhenhai Refinery 1 yuta ton/taun proyek etilena

Bahan welding kanggo wesi aluminium

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | N | |

| ATURAN GB/T | 0.04 | 0.5-2.0 | 1.00 | 21.5-23.5 | 7.5-10.5 | 2.5-3.5 | 0.04 | 0.03 | 0.08-0.20 | |

| ATURAN AWS | 0.04 | 0.5-2.0 | 1.00 | 21.5-23.5 | 8.5-10.5 | 2.5-3.5 | 0.04 | 0.03 | 0.08-0.2 | |

| NILAI CONTOH | 0,026 | 0.75 | 0.65 | 22.8 | 9.4 | 3.3 | 0,028 | 0.005 | 0.14 | |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | NILAI IMPAK J/℃ | ELONGASI(%) | ||||

| ATURAN GB/T | - | 690 | - | 15 | ||||

| ATURAN AWS | - | 690 | - | 20 | ||||

| NILAI CONTOH | - | 835 | 40/-40 | 26 | ||||

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| LISTRIK (Amp) | H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||

Tulis pesen sampeyan ing kene lan kirimake menyang kita