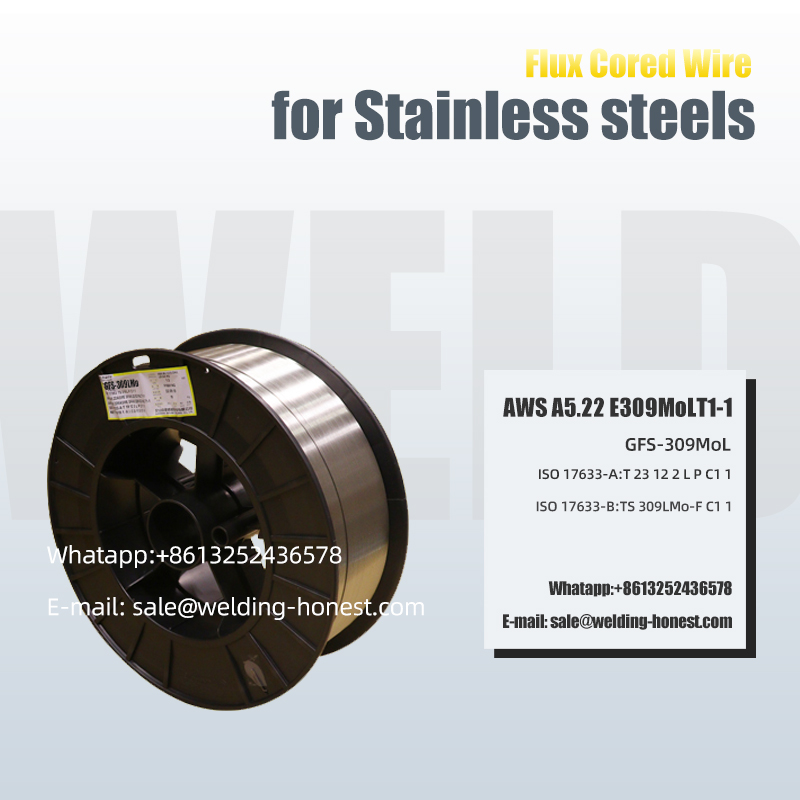

CESstainless steels Flux cored wire E309LMoT1-1 Seal makings

TEKNOLOGI WELDING

Aja nganti pitakonan

Terus ngganggu sampeyan

Ketidakstabilan Arc

Molding sing ora apik

Kakehan spatter

kinerja proses welding banget

Logam las ngandhut luwih ferrite lan sensitivitas retak kurang

Ripple apik

Cocog kanggo welding baja beda saka

stainless steel, baja karbon lan baja paduan rendah

Welding ngisor saka stainless steel cladding plate cladding, ngisor

welding saka 316 seri stainless steel lumahing ing baja karbon utawa baja alloy kurang

Gampang slagging

Parameter produk

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| ATURAN GB/T | 0.04 | 0.5-2.5 | 1.00 | 21.0-25.0 | 12.0-16.0 | 2.0-3.0 | 0.04 | 0.03 | 0.75 | |

| ATURAN AWS | 0.04 | 0.5-2.5 | 1.00 | 21.0-25.0 | 12.0-16.0 | 2.0-3.0 | 0.04 | 0.03 | 0.75 | |

| NILAI CONTOH | 0,025 | 1.3 | 0.6 | 23.68 | 12.5 | 2.5 | 0.02 | 0,050 | 0.02 | |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | NILAI IMPAK J/℃ | ELONGASI(%) | ||||

| ATURAN GB/T | - | 520 | - | 15 | ||||

| ATURAN AWS | - | 520 | - | 25 | ||||

| NILAI CONTOH | - | 600 | - | 30 | ||||

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 1.2 | 1.6 | ||||||

| Volt | 22-36 | 26-38 | ||||||

| Amp | 120-260 | 200-300 | ||||||

| dawa ekstensi garing (mm) | 15-20 | 18-25 | ||||||

| Aliran gas (l/min) | 15-25 | 15-25 | ||||||

Dhukungan pabrik

Produk kasebut cocog kanggo a

sawetara saka sudhut aplikasi

TEKNOLOGI WELDING

Zhejiang Petrokimia

40 yuta ton/taunnyaring

lan proyek integrasi kimia

Zhangjiagang Hanzhong Cryogenic

Teknologi Co., LTD. Kriogenik

wadhah panyimpenan lan transportasi

174.000 meter kubik

gas alam cair (LNG)

kapal Chung Nongbok Seok

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| ATURAN GB/T | 0.04 | 0.5-2.5 | 1.00 | 21.0-25.0 | 12.0-16.0 | 2.0-3.0 | 0.04 | 0.03 | 0.75 | |

| ATURAN AWS | 0.04 | 0.5-2.5 | 1.00 | 21.0-25.0 | 12.0-16.0 | 2.0-3.0 | 0.04 | 0.03 | 0.75 | |

| NILAI CONTOH | 0,025 | 1.3 | 0.6 | 23.68 | 12.5 | 2.5 | 0.02 | 0,050 | 0.02 | |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | NILAI IMPAK J/℃ | ELONGASI(%) | ||||

| ATURAN GB/T | - | 520 | - | 15 | ||||

| ATURAN AWS | - | 520 | - | 25 | ||||

| NILAI CONTOH | - | 600 | - | 30 | ||||

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 1.2 | 1.6 | ||||||

| Volt | 22-36 | 26-38 | ||||||

| Amp | 120-260 | 200-300 | ||||||

| dawa ekstensi garing (mm) | 15-20 | 18-25 | ||||||

| Aliran gas (l/min) | 15-25 | 15-25 | ||||||