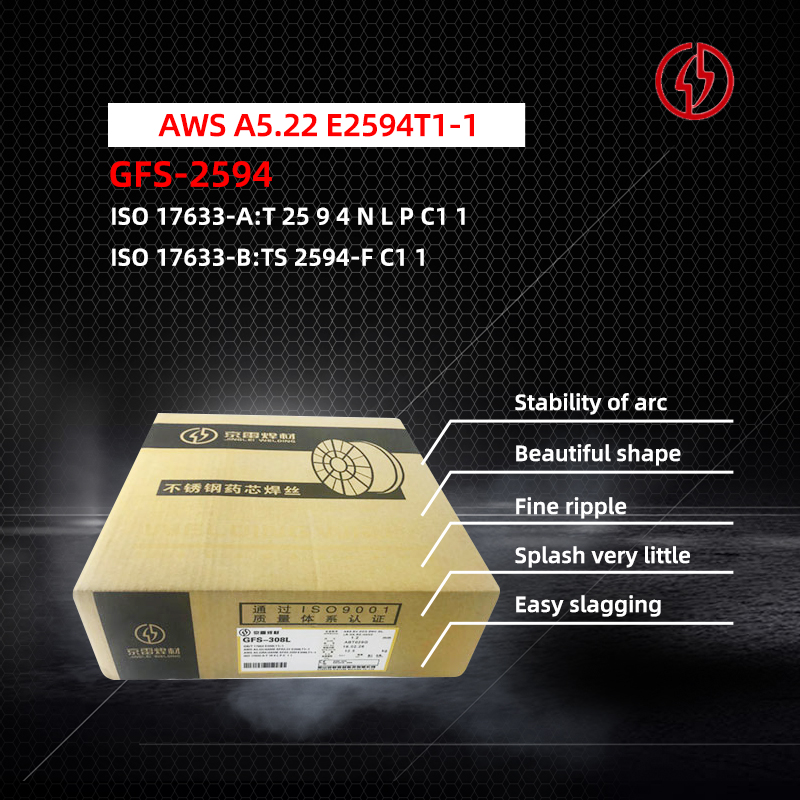

Baja tahan karat Flux cored wire E2594T1-1 metal Jointing stuff

Aplikasi

Ditrapake kanggo welding saka 25% Cr baja duplex kayata super duplex stainless steel UNS S32750 lan UNS J93380.

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | N | Cu | W | |

| ATURAN GB/T | 0.04 | 0.5-2.5 | 1.00 | 24.0-27.0 | 8.0-10.5 | 2.5-4.5 | 0.04 | 0.03 | 0.2-0.3 | 1.50 | 1.00 | |

| ATURAN AWS | 0.04 | 0.5-2.5 | 1.00 | 24.0-27.0 | 8.0-10.5 | 2.5-4.5 | 0.04 | 0.03 | 0.2-0.3 | 1.50 | 1.00 | |

| NILAI CONTOH | 0,025 | 1.15 | 0.65 | 24.8 | 9 | 3.5 | 0.018 | 0.002 | 0.23 | 0.02 | 0.01 | |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | NILAI IMPAK J/℃ | ELONGASI(%) | ||||

| ATURAN GB/T | - | 760 | - | 13 | ||||

| ATURAN AWS | - | 760 | - | 15 | ||||

| NILAI CONTOH | - | 883 | - | 25 | ||||

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 1.2 | 1.6 | ||||||

| Volt | 22-36 | 26-38 | ||||||

| Amp | 120-260 | 200-300 | ||||||

| dawa ekstensi garing (mm) | 15-20 | 18-25 | ||||||

| Aliran gas (l/min) | 15-25 | 15-25 | ||||||

Kekhasan

Struktur mikro las yaiku struktur biphase ferit austenitik.

Resistance pitting sing apik banget, PREN (setara karo resistensi pitting) ≥40.

Busur alus lan stabil, kurang cipratan, mbentuk ayu, aman slag apik, kabel stabil dipakani, karo kinerja proses welding banget.

Nuduhake rincian

wangun ayu

Ngilangi slag sing apik

Babagan kita

Pabrik fioor tampilan

Kasus aplikasi

Bahan welding kanggo wadhah

China Science & Technology Co., LTD. 20 yuta ton / taun proyek panyulingan lan integrasi kimia

shooting pabrik nyata

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | N | Cu | W | |

| ATURAN GB/T | 0.04 | 0.5-2.5 | 1.00 | 24.0-27.0 | 8.0-10.5 | 2.5-4.5 | 0.04 | 0.03 | 0.2-0.3 | 1.50 | 1.00 | |

| ATURAN AWS | 0.04 | 0.5-2.5 | 1.00 | 24.0-27.0 | 8.0-10.5 | 2.5-4.5 | 0.04 | 0.03 | 0.2-0.3 | 1.50 | 1.00 | |

| NILAI CONTOH | 0,025 | 1.15 | 0.65 | 24.8 | 9 | 3.5 | 0.018 | 0.002 | 0.23 | 0.02 | 0.01 | |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | NILAI IMPAK J/℃ | ELONGASI(%) | ||||

| ATURAN GB/T | - | 760 | - | 13 | ||||

| ATURAN AWS | - | 760 | - | 15 | ||||

| NILAI CONTOH | - | 883 | - | 25 | ||||

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 1.2 | 1.6 | ||||||

| Volt | 22-36 | 26-38 | ||||||

| Amp | 120-260 | 200-300 | ||||||

| dawa ekstensi garing (mm) | 15-20 | 18-25 | ||||||

| Aliran gas (l/min) | 15-25 | 15-25 | ||||||

Tulis pesen sampeyan ing kene lan kirimake menyang kita