Paduan nikel TIG ERNiCrFe-7A Soldering jointing

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | Nb+Ta | P | S |

| ATURAN GB/T | - | - | - | - | - | - | - | - | - | - |

| ATURAN AWS | 0.04 | 1.00 | 0.50 | 28.0-31.5 | Rem | 0.50 | 7.0-11.0 | 0.5-1.0 | 0.02 | 0.015 |

| NILAI CONTOH | 0,028 | 0.15 | 0.11 | 29.8 | 59.03 | 0.06 | 9.8 | 0.86 | 0.001 | 0.002 |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | NILAI IMPAK J/℃ | ELONGASI(%) | perawatan panas | ||||||

| ATURAN GB/T | - | - | - | - | - | ||||||

| ATURAN AWS | - | - | - | - | - | ||||||

| NILAI CONTOH | - | 760 | 133 / Suhu kamar | 37 | 607°C*25h | ||||||

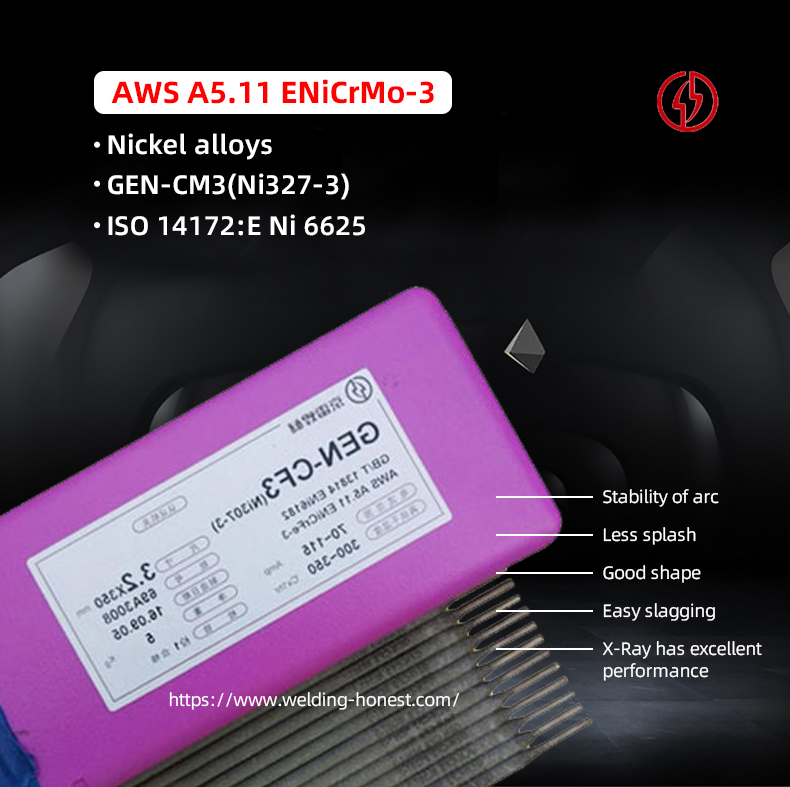

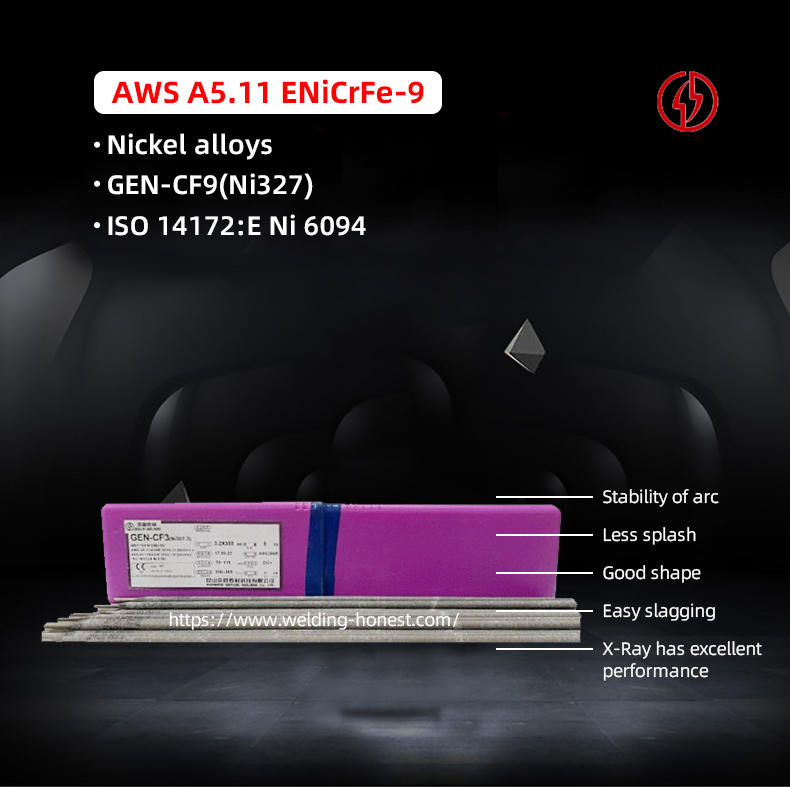

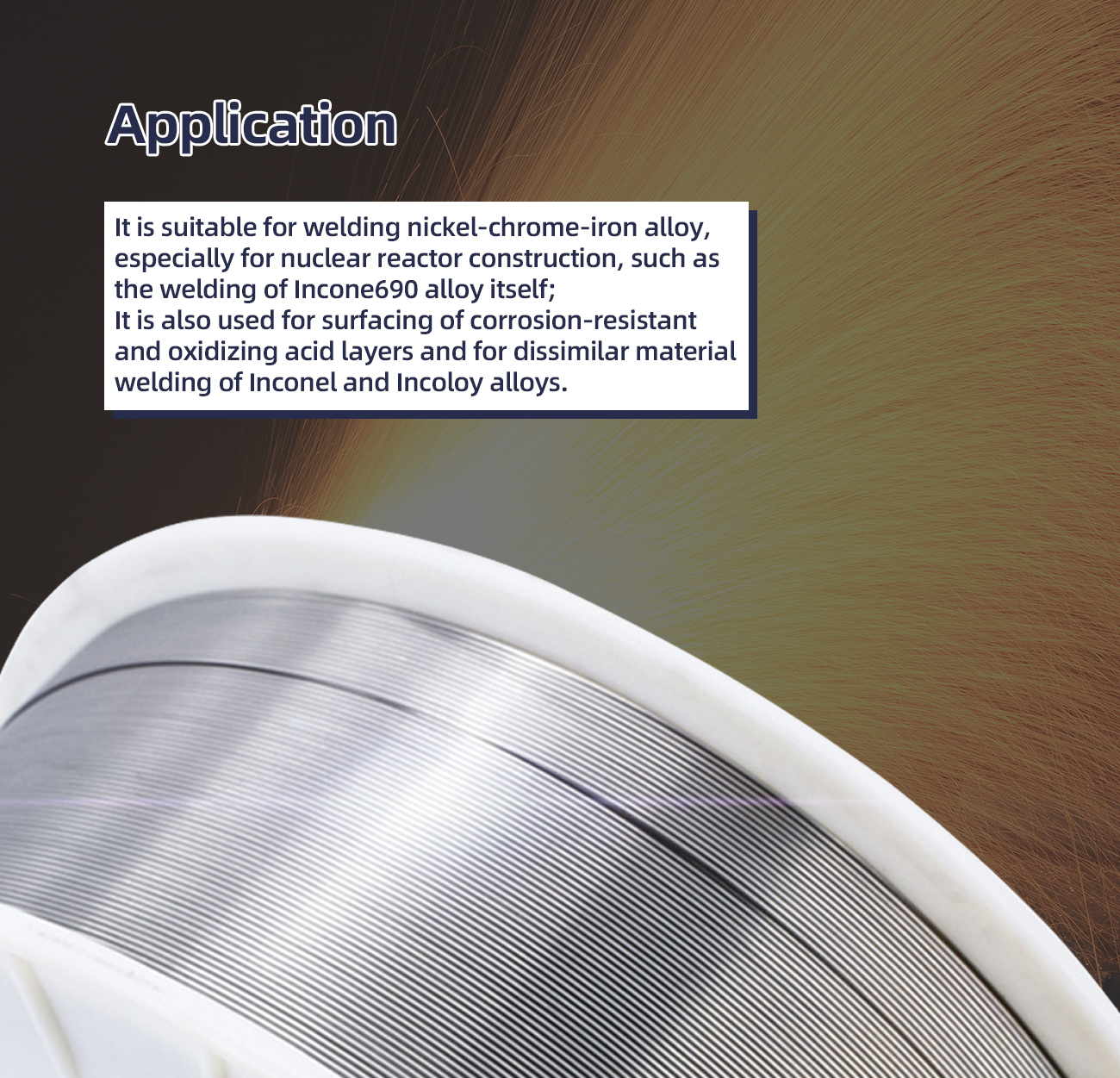

Nikel-kromium-wesi nikel-base alloy gas kawat las, komposisi nominal 60% Ni-29% Cr-9% Fe-0,75% Nb.

Sifat mekanik sing apik saka logam molten, utamane tahan kanggo retak plastik kurang (DDC).

Isi Cr sing dhuwur ndadekake resistensi korosi stres sing apik banget ing lingkungan banyu murni ing kondisi radiasi. Stabil busur, ayu mbentuk, aliran apik saka wesi molten, karo kinerja proses welding banget.

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | Nb+Ta | P | S |

| ATURAN GB/T | - | - | - | - | - | - | - | - | - | - |

| ATURAN AWS | 0.04 | 1.00 | 0.50 | 28.0-31.5 | Rem | 0.50 | 7.0-11.0 | 0.5-1.0 | 0.02 | 0.015 |

| NILAI CONTOH | 0,028 | 0.15 | 0.11 | 29.8 | 59.03 | 0.06 | 9.8 | 0.86 | 0.001 | 0.002 |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | NILAI IMPAK J/℃ | ELONGASI(%) | perawatan panas | ||||||

| ATURAN GB/T | - | - | - | - | - | ||||||

| ATURAN AWS | - | - | - | - | - | ||||||

| NILAI CONTOH | - | 760 | 133 / Suhu kamar | 37 | 607°C*25h | ||||||

Tulis pesen sampeyan ing kene lan kirimake menyang kita