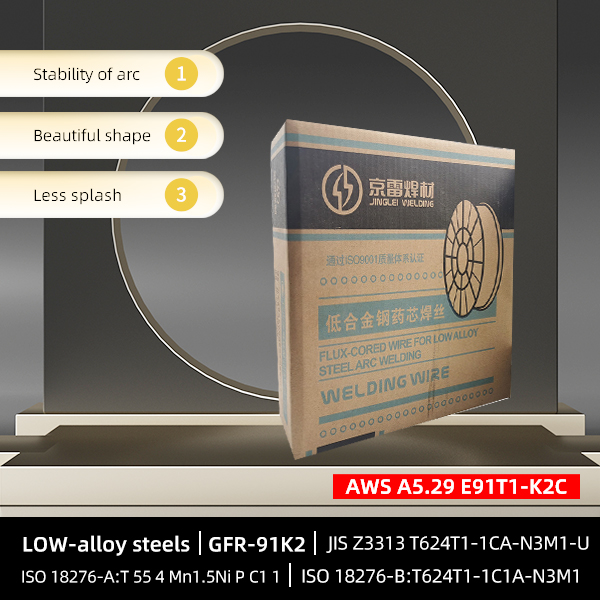

Baja paduan rendah Flux cored wire E91T1-K2C barang fabrikasi las

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S |

| ATURAN GB/T | 0.15 | 0.50-1.75 | 0.80 | 0.15 | 1.00-2.00 | 0.35 | 0.03 | 0.03 |

| ATURAN AWS | 0.15 | 0.50-1.75 | 0.80 | 0.15 | 1.00-2.00 | 0.35 | 0.03 | 0.03 |

| NILAI CONTOH | 0.045 | 1.3 | 0.28 | 0.03 | 1.86 | 0.21 | 0.01 | 0.005 |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | NILAI IMPAK J/℃ | ELONGASI(%) | Perlakuan panas°Cxh | |||||

| ATURAN GB/T | 530 | 620-820 | 27/-40 | 15 | AW | |||||

| ATURAN AWS | 540 | 620-760 | 27/-20 | 17 | AW | |||||

| NILAI CONTOH | 650 | 725 | 93/-40 | 25 | AW | |||||

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 1.2 | 1.4 | 1.6 | |||||||

| Volt | 25-32 | 24-36 | 25-40 | |||||||

| Amp | 150-300 | 170-360 | 200-400 | |||||||

| dawa ekstensi garing (mm) | 15-20 | 15-20 | 18-25 | |||||||

| Aliran gas (l/min) | 15-25 | 15-25 | 15-25 | |||||||

Komponen utama yaiku 1,5% Ni.

Busur iku alus lan stabil, kurang cipratan, mbentuk ayu, aman slag apik.

Kurang soot, karo kinerja proses welding banget.

-

158.000 ton kapal tanker Suez

-

Situs lumahing tabung GDS-2209/GXS-E330

Zhangjiagang CIMC Sundayin Cryogenic Equipment Co., LTD. Cryogenic Container (Stasiun Pengisian LNG)

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S |

| ATURAN GB/T | 0.15 | 0.50-1.75 | 0.80 | 0.15 | 1.00-2.00 | 0.35 | 0.03 | 0.03 |

| ATURAN AWS | 0.15 | 0.50-1.75 | 0.80 | 0.15 | 1.00-2.00 | 0.35 | 0.03 | 0.03 |

| NILAI CONTOH | 0.045 | 1.3 | 0.28 | 0.03 | 1.86 | 0.21 | 0.01 | 0.005 |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | NILAI IMPAK J/℃ | ELONGASI(%) | Perlakuan panas°Cxh | |||||

| ATURAN GB/T | 530 | 620-820 | 27/-40 | 15 | AW | |||||

| ATURAN AWS | 540 | 620-760 | 27/-20 | 17 | AW | |||||

| NILAI CONTOH | 650 | 725 | 93/-40 | 25 | AW | |||||

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 1.2 | 1.4 | 1.6 | |||||||

| Volt | 25-32 | 24-36 | 25-40 | |||||||

| Amp | 150-300 | 170-360 | 200-400 | |||||||

| dawa ekstensi garing (mm) | 15-20 | 15-20 | 18-25 | |||||||

| Aliran gas (l/min) | 15-25 | 15-25 | 15-25 | |||||||

Tulis pesen sampeyan ing kene lan kirimake menyang kita