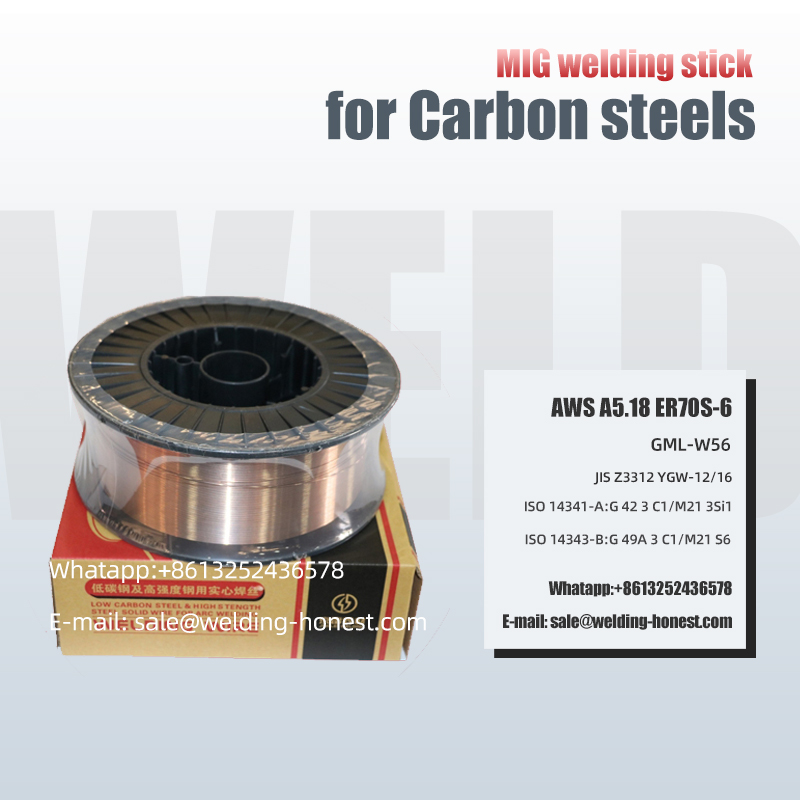

Baja paduan rendah Flux cored wire E71T-1C-J Seal stuff

Aplikasi

Cocog kanggo kapal, jembatan, konstruksi, platform lepas pantai, pipa, welding struktur baja.

Standar sing kita temoni: GB/T10045 T 49 4 T1-1 C1 P , AWS A5.20 E71T-1C-J & A5.20M E491T-1C-J, ISO17632-A:T42 4 P C1 1, ISO 17632-B :T49 4 T1-1 C1 P.

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| ATURAN GB/T | 0.18 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| ATURAN AWS | 0.12 | 1.75 | 0.90 | 0.20 | 0.50 | 0.30 | 0.03 | 0.03 | 0.08 |

| NILAI CONTOH | 0.040 | 1.200 | 0.30 | 0.02 | 0.45 | 0.01 | 0.010 | 0.005 | 0.01 |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | HEATTREAMENT ℃ xh | NILAI IMPAK J/℃ | ELONGASI(%) | ||||

| ATURAN GB/T | 390 | 490-670 | AW | 27/-40 | 18 | ||||

| ATURAN AWS | 390 | 490-670 | AW | 27/-40 | 22 | ||||

| NILAI CONTOH | 495 | 560 | AW | 121/-40 | 31 | ||||

| NILAI CONTOH | 470 | 545 | 620*5 | 100/-40 | 30 | ||||

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 1.2 | 1.4 | 1.6 | ||||

| VOLT | 23-32 | 24-36 | 25-40 | ||||

| AMP | 150-300 | 170-360 | 200-400 | ||||

| DONGENG: MM | 15-20 | 15-20 | 18-25 | ||||

| L/MIN | 15-25 | 15-25 | 15-25 |

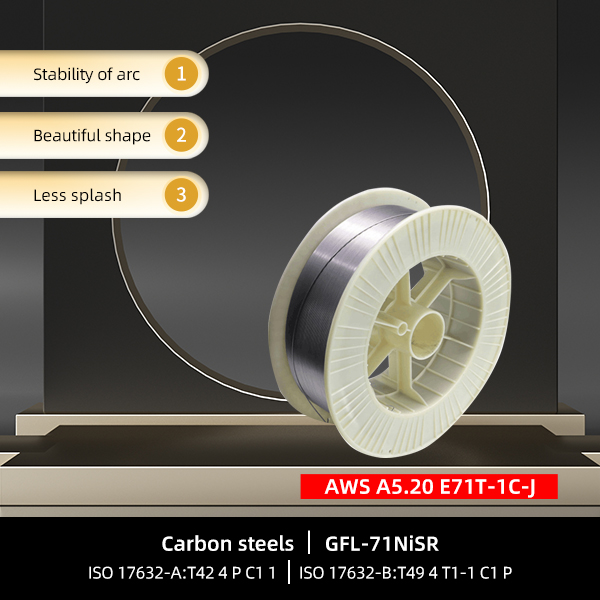

Kekhasan

Post-welding perawatan panas kasedhiya.

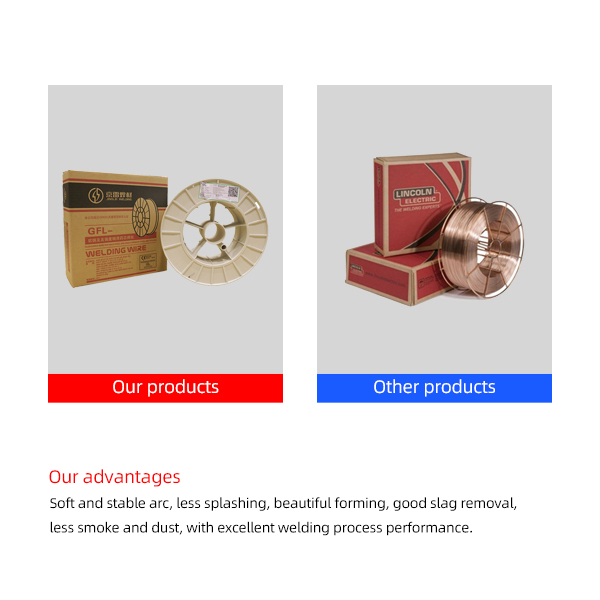

Busur alus lan stabil, kurang cipratan, mbentuk ayu, aman slag apik, kurang soot, karo kinerja proses welding banget.

Kinerja banget ing negara welding lan negara perawatan panas.

-40 ℃ kinerja impact suhu kurang apik banget, kinerja CTOD stabil.

Nuduhake rincian

Lembut lan stabil

Kurang cipratan

Babagan kita

Pabrik fioor tampilan

Kasus aplikasi

Sino-Rusia Front Wétan

Reaktor polipropilena

shooting pabrik nyata

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| ATURAN GB/T | 0.18 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| ATURAN AWS | 0.12 | 1.75 | 0.90 | 0.20 | 0.50 | 0.30 | 0.03 | 0.03 | 0.08 |

| NILAI CONTOH | 0.040 | 1.200 | 0.30 | 0.02 | 0.45 | 0.01 | 0.010 | 0.005 | 0.01 |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | HEATTREAMENT ℃ xh | NILAI IMPAK J/℃ | ELONGASI(%) | ||||

| ATURAN GB/T | 390 | 490-670 | AW | 27/-40 | 18 | ||||

| ATURAN AWS | 390 | 490-670 | AW | 27/-40 | 22 | ||||

| NILAI CONTOH | 495 | 560 | AW | 121/-40 | 31 | ||||

| NILAI CONTOH | 470 | 545 | 620*5 | 100/-40 | 30 | ||||

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 1.2 | 1.4 | 1.6 | ||||

| VOLT | 23-32 | 24-36 | 25-40 | ||||

| AMP | 150-300 | 170-360 | 200-400 | ||||

| DONGENG: MM | 15-20 | 15-20 | 18-25 | ||||

| L/MIN | 15-25 | 15-25 | 15-25 |

Tulis pesen sampeyan ing kene lan kirimake menyang kita