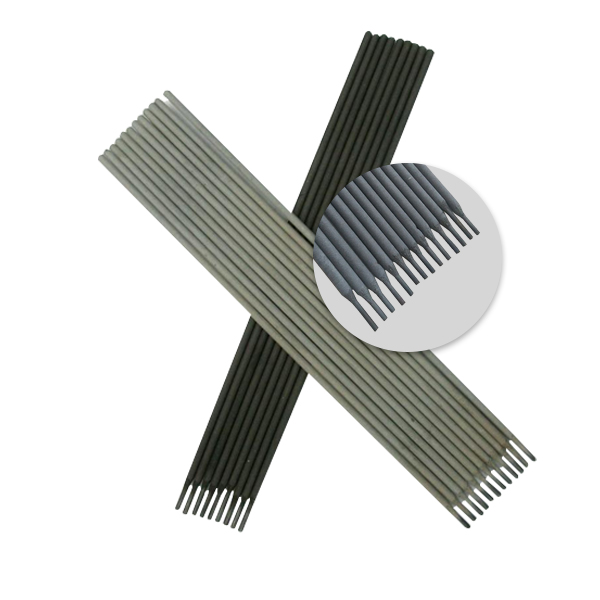

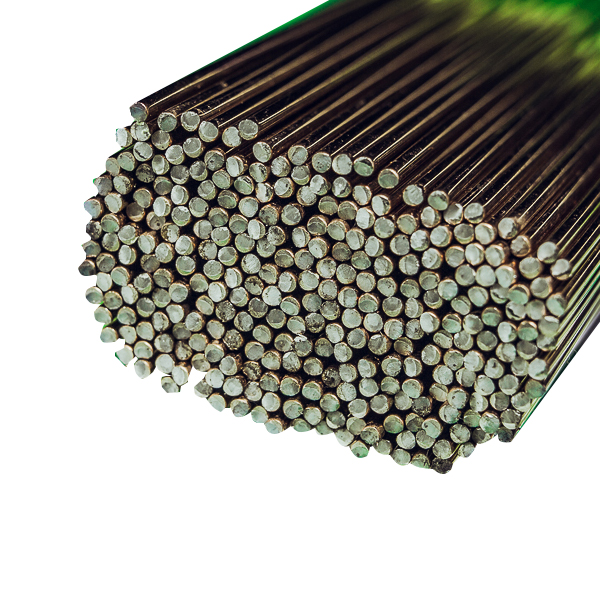

Baja Karbon Tinggi Elektroda manual E9818-G Soldering makings

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| ATURAN GB/T | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.20 | ≥0.10 |

| ATURAN AWS | - | - | - | - | - | - | - | - | - | - |

| NILAI CONTOH | 0,050 | 1.50 | 0.27 | 0.83 | 3.35 | 0.72 | 0.005 | 0.004 | 0.018 | 0.004 |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | HEATTREAMENT ℃ xh | NILAI IMPAK J/℃ | ELONGASI(%) | |||||

| ATURAN GB/T | - | - | - | - | - | |||||

| ATURAN AWS | - | - | - | - | - | |||||

| NILAI CONTOH | 915 | 992 | - | 65/-20 | 16 | |||||

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| LISTRIK (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | |||||

| O/W | 50-80 | 90-120 | 130-160 | - | ||||||

980Mpa kekuatan super dhuwur ferrohidrogen bubuk jinis elektroda baja paduan rendah.

Busur stabil, cipratan cilik, mbusak slag sing apik

Kinerja welding kabeh posisi sing apik, ketangguhan suhu sing apik, resistensi retak lan ketangguhan impact suhu sing sithik.

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| ATURAN GB/T | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.20 | ≥0.10 |

| ATURAN AWS | - | - | - | - | - | - | - | - | - | - |

| NILAI CONTOH | 0,050 | 1.50 | 0.27 | 0.83 | 3.35 | 0.72 | 0.005 | 0.004 | 0.018 | 0.004 |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | HEATTREAMENT ℃ xh | NILAI IMPAK J/℃ | ELONGASI(%) | |||||

| ATURAN GB/T | - | - | - | - | - | |||||

| ATURAN AWS | - | - | - | - | - | |||||

| NILAI CONTOH | 915 | 992 | - | 65/-20 | 16 | |||||

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| LISTRIK (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | |||||

| O/W | 50-80 | 90-120 | 130-160 | - | ||||||

Tulis pesen sampeyan ing kene lan kirimake menyang kita