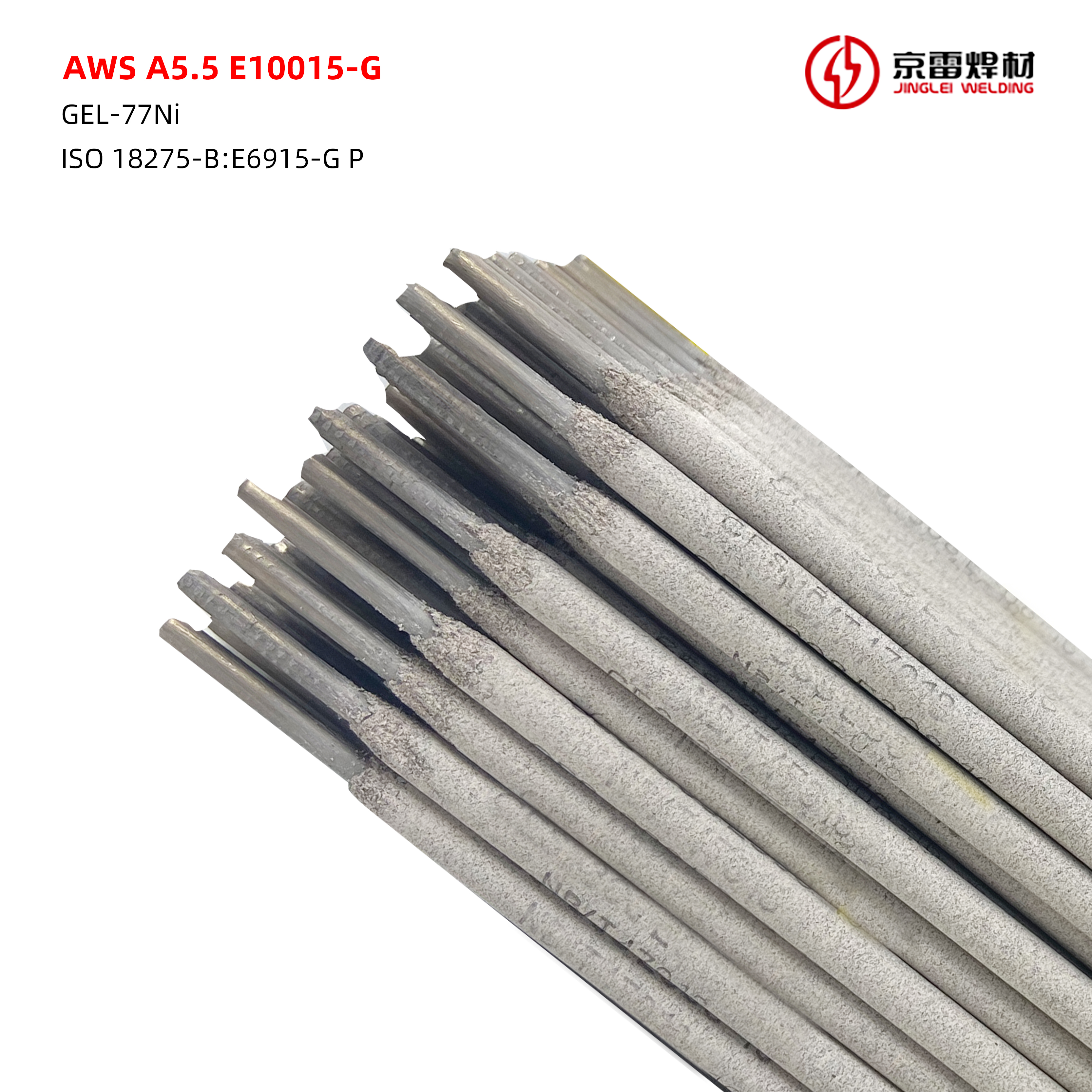

Baja Karbon Tinggi Elektroda manual E8015-G Seal jointing

Cocog kanggo welding baja karbon medium lan baja paduan rendah, uga kekuatan sing cocog saka prau meksa, petrokimia, tank bundher, teknik samudra, pipa, kapal, jembatan lan struktur liyane, kayata Q420, Q460, 15MnTi, 15MnV, X60 , las X70.

Standar sing kita temoni: GB/T5117 E5015-G AP, AWS A5.5 E8015-G & A5.5M E5515-G, ISO2560-A, ISO 2560-B: E5515-G AP

Apa sing

ciri khas?

●Low sodium hidrogen tangan elektroda, stabil busur, ayu mbentuk, nggoleki ripple.

●SPlash banget sethitik, gampang kanggo desagger, resistance geni kulit tamba apik, resistance stomata apik.

●Sifat mekanik sing stabil, plastisitas sing apik.

●Impact kateguhan lan crack resistance.

Parameter produk

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| ATURAN GB/T | - | - | - | - | - | - | - | - | - |

| ATURAN AWS | 0.15 | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | 0.030 | 0.030 | ≥0.10 |

| NILAI CONTOH | 0.070 | 1.34 | 0.36 | 0.03 | 0.42 | 0.26 | 0.014 | 0.007 | 0.001 |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | HEATTREAMENT ℃ xh | NILAI IMPAK J/℃ | ELONGASI(%) | ||||

| ATURAN GB/T | 460 | 550 | AW/620*1 | - | 17 | ||||

| ATURAN AWS | 460 | 550 | - | - | 19 | ||||

| NILAI CONTOH | 515 | 605 | 620*1 | 138/-40 | 26 | ||||

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| LISTRIK (Amp) | H/W | 80-110 | 110-130 | 130-180 | 180-230 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||

Delengen dalane

kita angkut

●Transportasi motor

●Pengiriman

Delengen

warenouse kita

Proyek-proyek kasebut

kita melu

●308.000 ton kapal minyak mentah VLCC

●300.000 ton Floating Production Storage Tanker (FPSO)

produk kita

marang donya

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| ATURAN GB/T | - | - | - | - | - | - | - | - | - |

| ATURAN AWS | 0.15 | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | 0.030 | 0.030 | ≥0.10 |

| NILAI CONTOH | 0.070 | 1.34 | 0.36 | 0.03 | 0.42 | 0.26 | 0.014 | 0.007 | 0.001 |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | HEATTREAMENT ℃ xh | NILAI IMPAK J/℃ | ELONGASI(%) | ||||

| ATURAN GB/T | 460 | 550 | AW/620*1 | - | 17 | ||||

| ATURAN AWS | 460 | 550 | - | - | 19 | ||||

| NILAI CONTOH | 515 | 605 | 620*1 | 138/-40 | 26 | ||||

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| LISTRIK (Amp) | H/W | 80-110 | 110-130 | 130-180 | 180-230 | ||||

| O/W | 50-80 | 90-120 | 130-160 | - | |||||