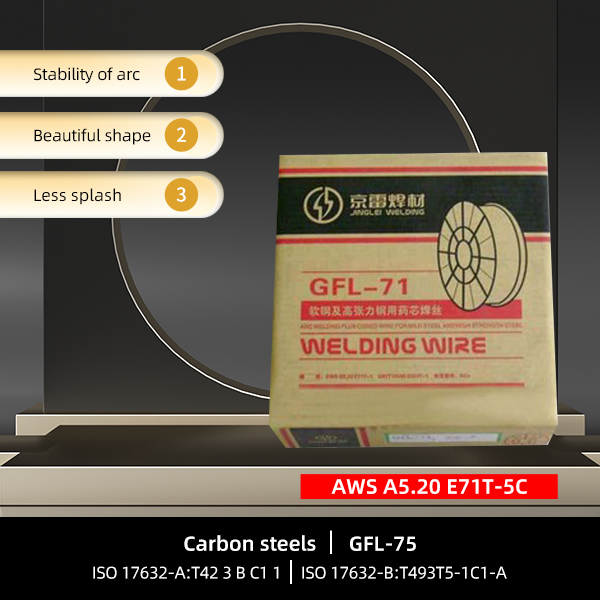

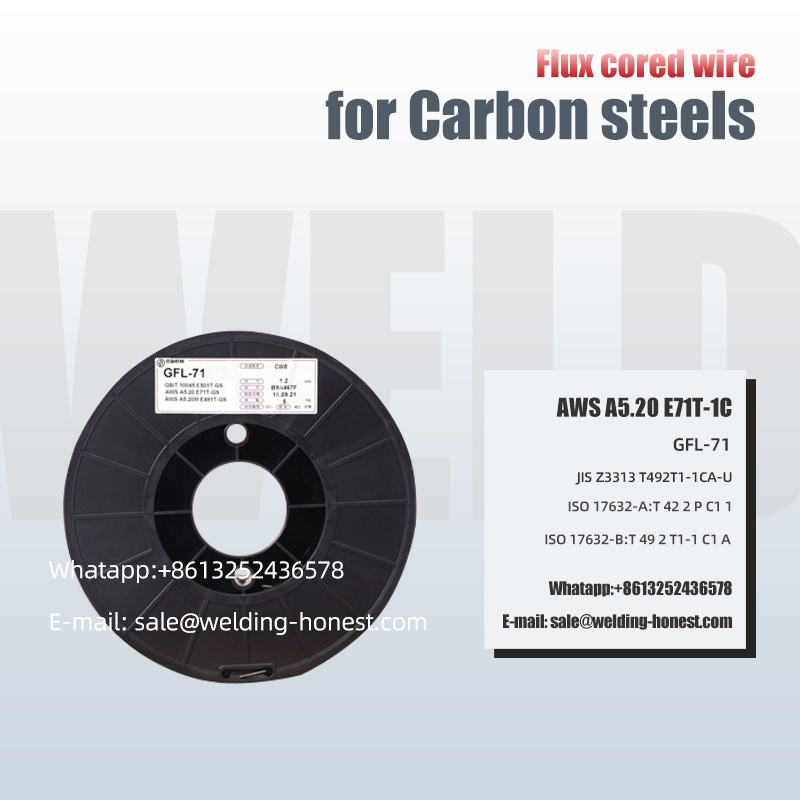

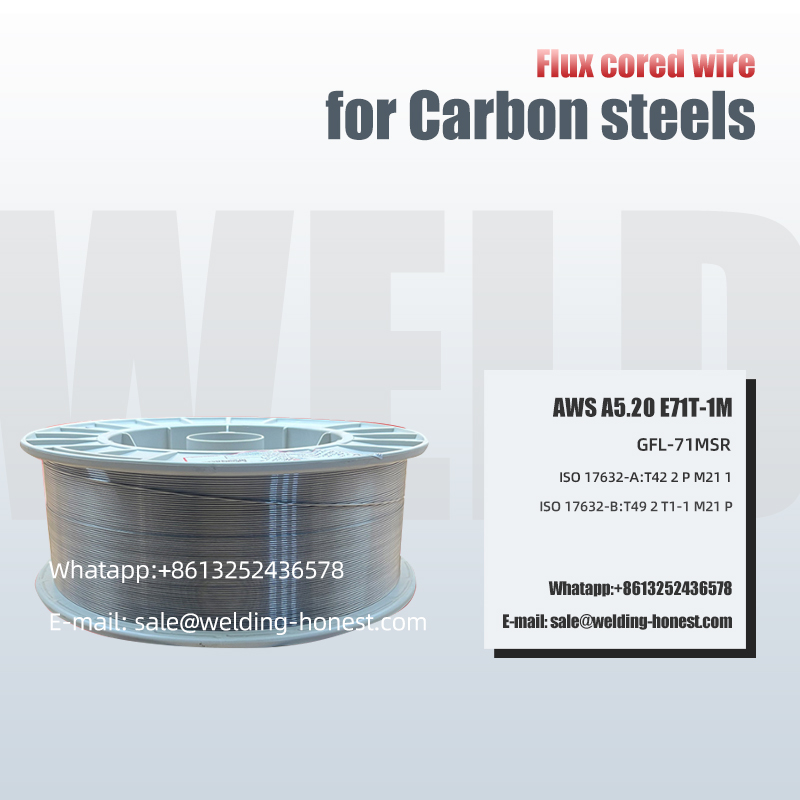

Baja Karbon Tinggi Flux cored wire E71T-5C welding makings

Aplikasi

Cocog kanggo prau tekanan, galangan kapal, platform lepas pantai, welding struktur baja.

Standar sing ditemoni: GB/T10045 T 49 3 T5-1 C1 A , AWS A5.20 E71T-5C & A5.20M E491T-5C, ISO17632-A: T42 3 B C1 1, ISO 17632-T493T5-1C .

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| ATURAN GB/T | 0.18 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| ATURAN AWS | 0.12 | 1.75 | 0.90 | 0.20 | 0.50 | 0.30 | 0.03 | 0.03 | 0.08 |

| NILAI CONTOH | 0.080 | 1.50 | 0.08 | 0.01 | 0.48 | 0.01 | 0.010 | 0.002 | 0.01 |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | HEATTREAMENT ℃ xh | NILAI IMPAK J/℃ | ELONGASI(%) | ||||

| ATURAN GB/T | 390 | 490-670 | AW | 27/-30 | 18 | ||||

| ATURAN AWS | 390 | 490-670 | AW | 27/-30 | 22 | ||||

| NILAI CONTOH | 450540 | 550 | AW | 80/-30 | 26 | ||||

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 1.2 | ||||||

| VOLT | 20-25 | ||||||

| AMP | 160-250 | ||||||

| MM | 15-25 | ||||||

| L/MIN | 20-25 | ||||||

Kekhasan

Sifat mekanik logam sing digabungake stabil.

Resistance retak lan resistance pori apik

Tingkat pass X-ray dhuwur.

Nuduhake rincian

resistance retak apik lan resistance porositas

X-Ray nduweni tingkat pass dhuwur

Babagan kita

Pabrik fioor tampilan

Kasus aplikasi

Proyek Kilang Sinopec

Zhangjiagang Hanzhong Cryogenic Technology Co., LTD. Wadhah panyimpenan lan transportasi suhu rendah

shooting pabrik nyata

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| ATURAN GB/T | 0.18 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| ATURAN AWS | 0.12 | 1.75 | 0.90 | 0.20 | 0.50 | 0.30 | 0.03 | 0.03 | 0.08 |

| NILAI CONTOH | 0.080 | 1.50 | 0.08 | 0.01 | 0.48 | 0.01 | 0.010 | 0.002 | 0.01 |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | HEATTREAMENT ℃ xh | NILAI IMPAK J/℃ | ELONGASI(%) | ||||

| ATURAN GB/T | 390 | 490-670 | AW | 27/-30 | 18 | ||||

| ATURAN AWS | 390 | 490-670 | AW | 27/-30 | 22 | ||||

| NILAI CONTOH | 450540 | 550 | AW | 80/-30 | 26 | ||||

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 1.2 | ||||||

| VOLT | 20-25 | ||||||

| AMP | 160-250 | ||||||

| MM | 15-25 | ||||||

| L/MIN | 20-25 | ||||||

Tulis pesen sampeyan ing kene lan kirimake menyang kita