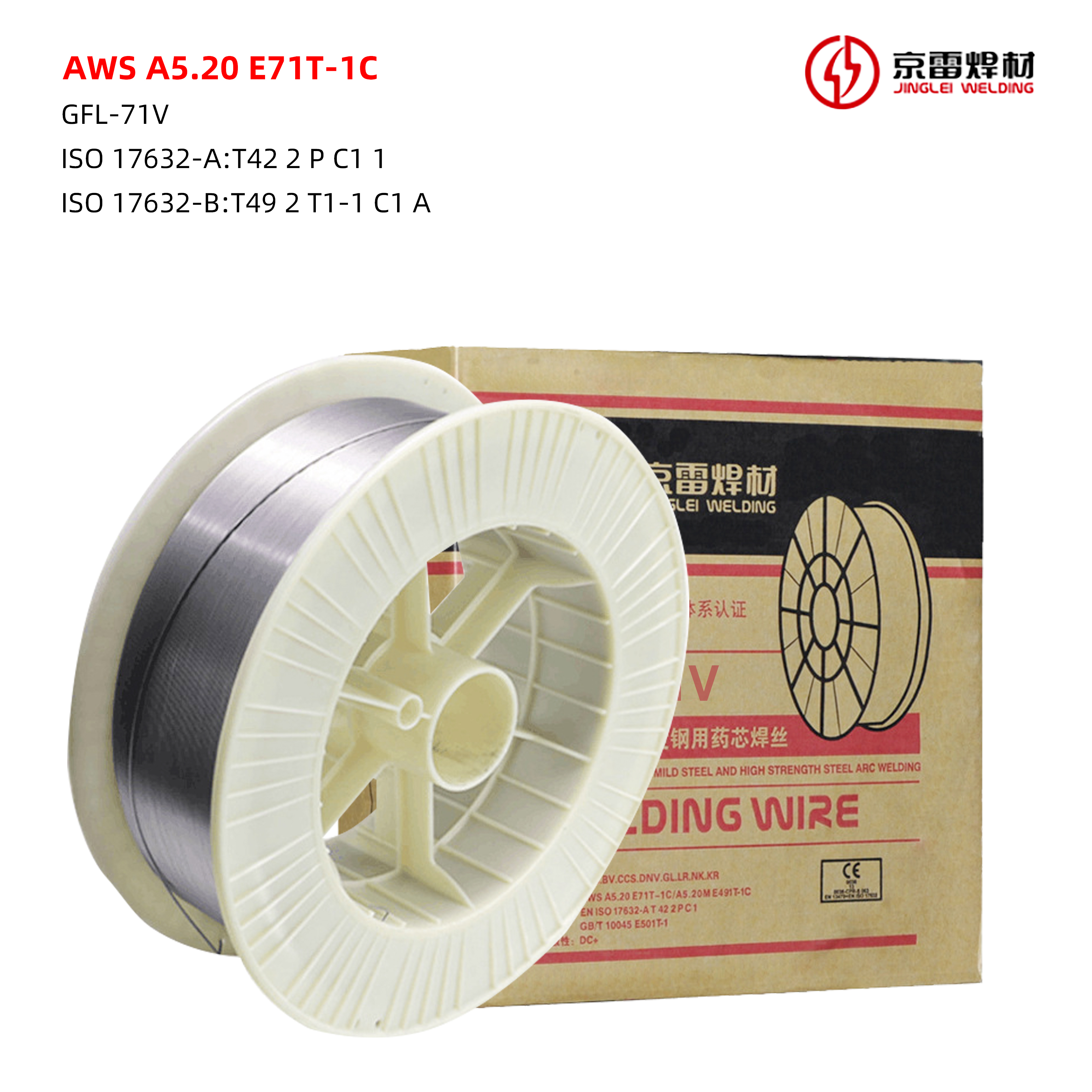

Baja Karbon Dhuwur CO2 Protect E70T-1C Flux cored wire welding accessories

Aplikasi & Standar

1. Cocog kanggo welding warata lan welding fillet kapal, Bridges, mesin, kendaraan lan struktur baja.

2. Standar sing kita temoni:

GB/T10045 T49 2 T15-0 C1 A, AWS A5.20 E70T-1C & A5.20M E490T-1C, ISO17632-A:T 42 2 R C1 3, ISO 17632-B:T49 2 T15-1 C1 AJIS Z3313 T492T15-1CA-U

3.Bisa digunakake kanggo welding saka baja cast utawa medium plate nglukis.

Fitur

1. Busur alus lan stabil, kurang cipratan, mbentuk ayu, aman slag apik, kurang soot, karo kinerja proses welding banget.

2. resistance banget kanggo priming, resistance apik kanggo porosity lan retak.

Perusahaan & Pabrik

Komposisi produk lan sifat mekanik introduksi

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| ATURAN GB/T | 0.18 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| ATURAN AWS | 0.12 | 1.75 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| NILAI CONTOH | 0.045 | 1.45 | 0.50 | 0.02 | 0.02 | 0.01 | 0.012 | 0.006 | 0.01 |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | HEATTREAMENT ℃ xh | NILAI IMPAK J/℃ | ELONGASI(%) | ||||

| ATURAN GB/T | 390 | 490-670 | AW | 27/-20 | 18 | ||||

| ATURAN AWS | 390 | 490-670 | AW | 27/-20 | 22 | ||||

| NILAI CONTOH | 500 | 575 | AW | 60/-20 | 27 | ||||

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 1.2 | 1.4 | 1.6 | ||||

| VOLT | 23-34 | 24-42 | 25-46 | ||||

| AMP | 150-320 | 170-400 | 200-450 | ||||

| MM | 15-20 | 15-20 | 18-25 | ||||

| L/MIN | 15-25 | 15-25 | 15-25 |

CATETAN:

CO2 Nglindhungi gas, pra-panas: 150±15 ℃

OTORITAS SERTIFIKASI: ABS/BV/CCS/DNV/GL/LR/NK/CE/JIS

KASUS KHAS

Sertifikat

KOMPONEN KIMIA:

| ALLOY (wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| ATURAN GB/T | 0.18 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| ATURAN AWS | 0.12 | 1.75 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| NILAI CONTOH | 0.045 | 1.45 | 0.50 | 0.02 | 0.02 | 0.01 | 0.012 | 0.006 | 0.01 |

PROPERTI MEKANIKAL:

| PROPERTI | KEKUATAN PENGHASILAN (MPa) | KEKUATAN EXTENSION (MPa) | HEATTREAMENT ℃ xh | NILAI IMPAK J/℃ | ELONGASI(%) | ||||

| ATURAN GB/T | 390 | 490-670 | AW | 27/-20 | 18 | ||||

| ATURAN AWS | 390 | 490-670 | AW | 27/-20 | 22 | ||||

| NILAI CONTOH | 500 | 575 | AW | 60/-20 | 27 | ||||

PARAMETER WELDING REKOMENDASI:

| SPESIFIKASI DIAMETER (mm) | 1.2 | 1.4 | 1.6 | ||||

| VOLT | 23-34 | 24-42 | 25-46 | ||||

| AMP | 150-320 | 170-400 | 200-450 | ||||

| MM | 15-20 | 15-20 | 18-25 | ||||

| L/MIN | 15-25 | 15-25 | 15-25 |

CATETAN:

CO2 Nglindhungi gas, pra-panas: 150±15 ℃

OTORITAS SERTIFIKASI: ABS/BV/CCS/DNV/GL/LR/NK/CE/JIS